Industrial IT systems

System for passporting and inspecting Ex equipment

Inspector-Ex®

Inspector-Ex® is a system supporting the operation of equipment in explosive atmospheres. It is a powerful and helpful tool for maintenance teams and people responsible for the operation of electrical equipment in facilities with potentially explosive zones.

Functionality

The Inspector-Ex® system facilitates the operation, passporting, as well as management of equipment and installations using modern mobile technology.

|

| Passporting: |

|

|

| Inspections: |

|

|

| Reports: |

|

|

| Planning: |

|

|

| Reliability: |

|

|

| State-of-the-art technology: |

|

Multiple benefits in a single solution

- The system guarantees a company’s compliance with regulations.

- You can be sure that the inspection has been carried out.

- Shorter inspection time (less labour‑intensive inspections).

- Direct and quick access to the required and current reports in case of an inspection authority’s request.

- Full optimisation and predictability of ownership costs.

- Reduced number of qualified personnel engaged in inspections.

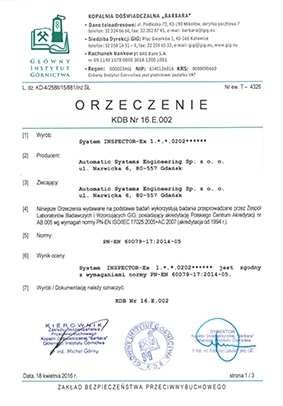

Certified safety

Decision KDB No. 16.E.002 for the Inspector-Ex® system

The Inspector-Ex® system was successfully certified by the Barbara Experimental Mine (a notified body of the Polish Central Mining Institute). An independent third party has confirmed that the Inspector-Ex® system complies with the requirements of: PN-EN 60079-17:2014 Explosive atmospheres – Part 17: Electrical installations inspection and maintenance.

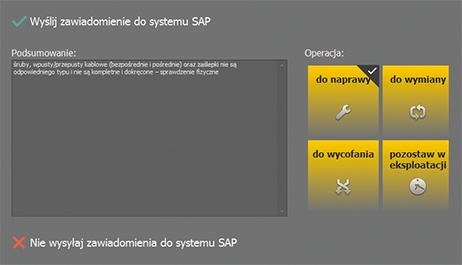

As part of operation management, the Inspector-Ex® system allows you to:

|

|

Comprehensive safety system

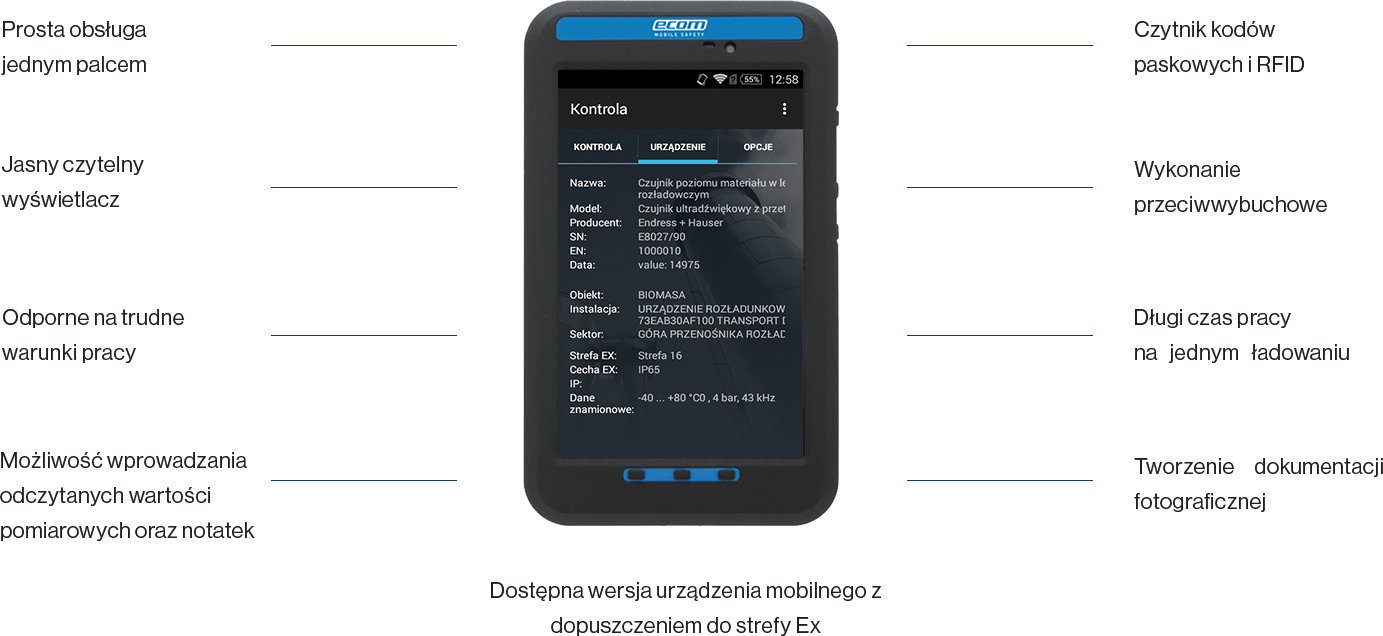

Mobile app adapted for harsh operating conditions

Inspector-Ex® system modules:

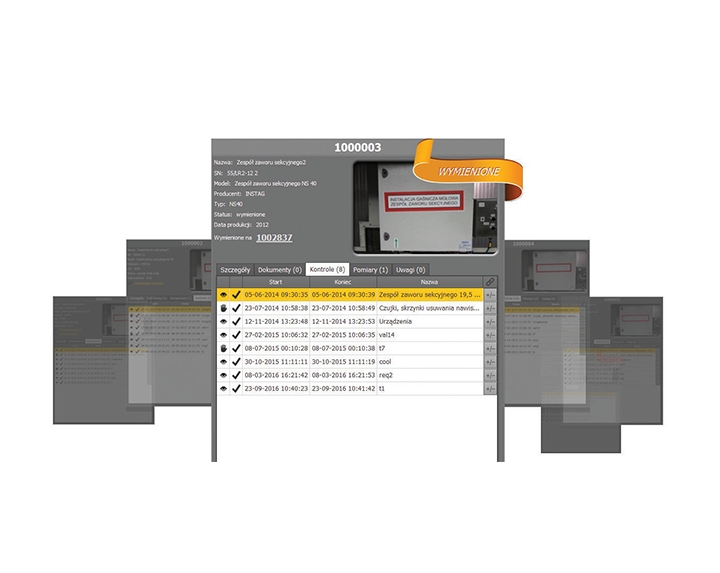

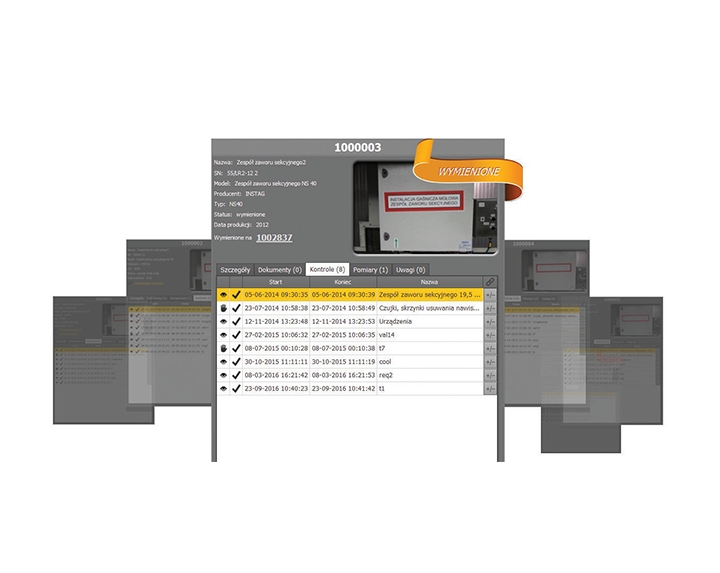

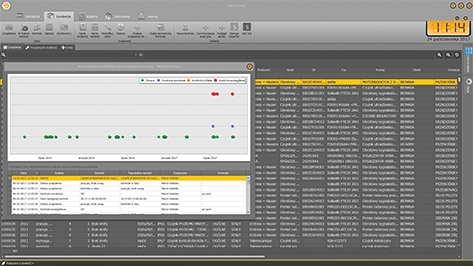

An operator of the system has maximum control and monitoring capabilities, both in terms of the current state of the plant, as well as any devices.

Autonomous supervising module (AUR) – integrated software for inspections of installations, nodes and critical equipment.

- The module supports the supervising work of the staff.

- A planned inspection route excludes the possibility of an omission.

- A well thought-out route reduces the time necessary to perform the work.

- Complete range of customised modifications.

LDAR (Leak Detection and Repair) module – module for maintenance at sites controlling fugitive leakages of volatile organic compounds.

The Inspector-LDAR system supports the LDAR software as regards:

- equipment records,

- emission spots tagging (QR, RFID),

- measurements input (current readings),

- exceeding notification with an alert and a repair job (in the form of a report),

- photographic documentation (also in the IR technology),

- interoperation with an OGI thermal camera – EyeCGas® VOC,

- interoperation with, e.g. SAP.

SVC module – supporting and coordinating the work of field maintenance teams.

- Equipment records and QR or RFID tagging.

- Service technician records, place and time of the repair.

- Visualisation of the equipment and service teams location on a map.

- Convenient digital schedule.

- Digital archives and full history of maintenance works.

- Remote dispatch of maintenance teams.

- Confirmation of a maintenance visit at a specific location.

- Confirmation of a service technician’s presence by the device.

- Dedicated check lists.

- Photographic documentation with commentary.

- Electronic report following a service visit.

- Remote access to electronic service reports.

The Implementation Department offers the expansion of the system with additional functional modules in order to adapt it to the client’s needs.

More information can be found at www.inspectorex.pl